15358968703

Summary of basic principles of steelmaking

2022-06-15

Make iron before making steel. Steel comes from pig iron. Pig iron smelted from iron ore contains high carbon content and many impurities (such as silicon, manganese, phosphorus, sulfur, etc.). Therefore, pig iron lacks plast...

Production practice of particulate matter emission from activated carbon desulfurization and denitration

2022-06-15

Abstract: activated carbon desulfurization and denitration system can simultaneously remove SO2, NOx, particulate matter, heavy metals and other pollutants in sintering flue gas. At present, it is widely used in the process o...

Study on desulfurization technology of blast furnace gas

2022-06-15

Blast furnace gas is a by-product gas produced in the process of iron and steel production. Its output is huge, and it can provide fuel for other sections of iron and steel production or be used for power generation. There ar...

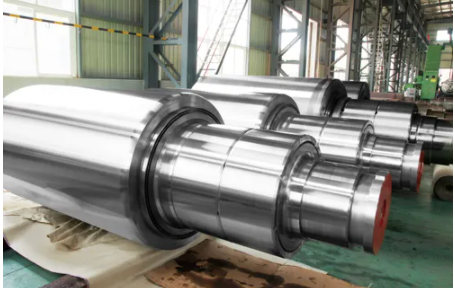

Characteristics and working principle of six high mill

2022-06-14

The traditional four high mill is a technology in the field of plate and strip rolling. With the increasing requirements for plate accuracy and shape, especially for the dimensional accuracy of strip, the shape control abilit...

When and how to add mold flux for continuous casting?

2022-06-14

In the actual production process, the performance of mold flux is closely related to the operation of adding slag. The continuous casting production practice in steel plants at home and abroad has proved that even if the mold...

Measures for improving AOD furnace life in refinery branch

2022-06-14

Abstract: in order to improve the AOD furnace life of MgO CA brick, the characteristics of MgO CA brick and MgO CR brick were compared, the erosion status in different areas of AOD furnace was analyzed, and the erosion in dif...