15358968703

Improvement and application of refractory for iron hook under low silicon ironmaking process

Abstract: in view of the accelerated erosion and scouring of the main iron trench due to the low viscosity and strong fluidity of molten iron after the implementation of low silicon iron making process in blast furnace, the electric melting of dense corundum, electric melting of white corundum powder, silicon carbide α- Al2O3 micropowder β- Iron channel castables were prepared with Si3N4 Powder, carbon, pure calcium aluminate cement, SiO2 micropowder and high-efficiency composite water reducer. The addition amount of 15 ~ 8mm large particle electrofusion dense corundum (5%, 10%, 15%) and β- Effect of Si3N4 Powder addition amount (mass fraction is 2%, 4%, 6%) on castable properties. The results show that the castables for the main trench are divided into iron wire castables with 10% (W) 15 ~ 8mm fused dense corundum and 6% (W) β- Si3N4 slag line castable and properly adjust the gradient of the main ditch have been applied to a 1080m3 low silicon iron making blast furnace ditch in Inner Mongolia. The results show that the problems of accelerated erosion and intensified scouring of the slag and iron line in the main ditch have been greatly improved, and the one-time iron flux has been increased from 100000 t to 150000 t.

Key words: low silicon ironmaking; Iron channel castable; Silicon nitride; Erosion resistance; Erosion resistance

Low silicon smelting in blast furnace can reduce coke ratio, increase output, improve pig iron quality, and improve technical and economic indicators [1]. The decrease of silicon content in molten iron can also improve the fluidity of molten iron and reduce the labor intensity of workers in front of the furnace; At the same time, the converter uses low silicon hot metal for steelmaking production, which can reduce the consumption of flux and oxygen, reduce the amount of slag, shorten the blowing time, and improve the effect of dephosphorization. It can be seen that low silicon smelting will bring good economic benefits to iron making and steelmaking. It has the advantages of improving hot metal quality, saving energy and reducing emissions, simplifying processes, etc., but it also puts forward more stringent requirements for refractory materials used in iron making system.

Through on-site sampling and analysis, the chemical composition (W) of iron slag is: cao40.17%, sio231.5%, Al2O3, 316.08%, mgo9.92%, fe2o30.75%, TiO2, 20.81%, s0.75% and mno0.40%. The XRD analysis of iron slag shows that the slag contains a large number of low melting point substances such as calcein, which accelerates the damage to the working lining. In addition, with the decrease of silicon content after low silicon smelting, the total iron content of molten iron increases, the viscosity decreases, the fluidity becomes stronger, and the scouring and permeability of molten iron become stronger during tapping. If the working lining forms a gap, it is very easy to infiltrate iron, resulting in a linear decline in the service life of the refractory used in the iron trench, and iron leakage is also easy to occur [2-4]. Therefore, it is necessary to improve the performance of refractory materials for iron trench under the condition of low silicon ironmaking process.

1. Test

The main raw materials used in the test are: fused dense corundum with w (Al2O3) ≥ 98% (particle size is 15 ~ 8, 8 ~ 5, 5 ~ 3, 3 ~ 1 and ≤ 1mm respectively), fused white corundum powder with w (Al2O3) ≥ 98.5% (particle size is ≤ 0.088mm), silicon carbide with w (SIC) ≥ 98% (particle size is ≤ 1 and ≤ 0.088mm respectively), w (Al2O3) ≥ 98.5% α- Al2O3 micro powder, w (Si3N4) ≥ 90% ≤ 5 μ M β- Si3N4 Powder, carbon, pure calcium aluminate cement, SiO2 micro powder and high efficiency composite water reducer, etc.

The test formula is shown in Table 1. Among them, 4\sample is the formula for improving the front main ditch material, 1\2\3\sample is the formula designed to improve the anti scouring performance of iron wire material, and 5\6\7\sample is the formula designed to improve the anti slag performance of slag wire material.

Weigh, stir and vibrate 40mm according to the formula in Table 1 × 40mm × The 160mm sample shall be cured for 24h in the environment with relative humidity <75%, and then naturally cured for 24h after demoulding. The sample shall be dried at 110 ℃ for 24h, and then heat treated at 1450 ℃ for 3h to test the performance indicators of the sample.

Test the chemical composition of the sample according to gb/t601, the bulk density of the sample according to yb/t5200-1993, the normal temperature compressive strength of the sample according to gb/t5072-2008, the linear change of the sample according to gb/t5988-2007, the high temperature flexural strength of the sample according to gb/t3002-2004, and the thermal shock resistance of the sample according to yb/t2206.2-1998.

Slag resistance: using the dynamic rotary slag resistance method, six samples of the size shown in Figure 1, which are dried at 110 ℃ for 24h, form a polygonal test panel as the lining of the rotary furnace, and a layer of magnesia is built between the sample and the metal furnace shell as the heat insulation material. Add the slag sample retrieved from the site, heat it with gas + oxygen, and stop the test after holding at 1450 ℃ for 5h. After that, cut the eroded sample from the middle along the longitudinal direction, and then measure the erosion depth of the sample section. The measurement points are selected from 10mm near the burner side of the sample, and one point is measured every 30mm to calculate the maximum erosion depth and average erosion depth.

2. Results and analysis

2.1 effect of large particle dense corundum addition on slag resistance of iron wire castables

See Fig. 2 for the slag resistance test results of 1\.

It can be seen from Figure 2 that with the increase of the amount of large particle aggregate, the corrosion resistance first increases and then decreases. The slag resistance of 2\. It shows that the addition of large particles can improve the hot metal scouring resistance of castables, but when the amount of large particles is too much, the matrix content decreases and the content of anti-corrosive raw materials (silicon carbide, etc.) decreases relatively on the same working face, which makes the scouring resistance of the samples worse.

2.2β- Effect of Si3N4 Powder addition on slag resistance of slag line castable

β- See Fig. 3 for the influence of Si3N4 Powder addition on slag resistance of slag line castable sample. It can be seen that the slag resistance is continuously improved with the increase of Si3N4 Powder. When Si3N4 Powder is added at 4% and 6% (W), the slag resistance of the material has little difference.

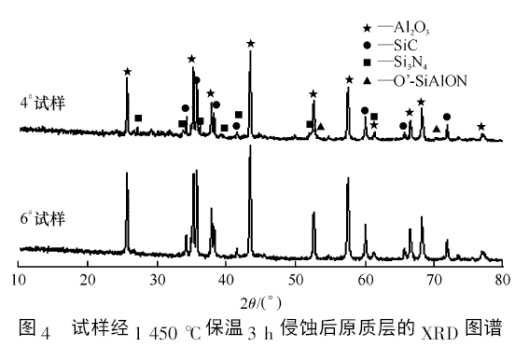

Not joined β- 4# sample and addition of Si3N4 Powder β- The average erosion depth of Si3N4 Powder 6# sample is 17.3 and 13.2mm respectively. The XRD analysis of the original layer after slag resistance is shown in Figure 4.

It can be seen from Figure 4 that Si3N4 can be partially retained during the sintering process, and o '-sialon phase is formed. Since the silicon nitride phase is not easy to be wetted by slag iron, the slag resistance of the material is enhanced [5]. Although the addition of silicon nitride has greatly improved the slag resistance of slag line castable, considering the cost performance, it is considered that when the addition amount is 4% (W), the performance of castable is greatly improved and the material cost is well controlled.

2.3 physical and chemical indexes of castables

See Table 2 for the physical and chemical properties of the main iron channel castable (4\), the iron line castable (2\\) and the slag line castable (6\\\. It can be seen that the addition of large particle aggregate or Si3N4 fine powder to the iron trench castable has little effect on the strength and thermal shock resistance of the castable, but can significantly improve the hot metal scouring and erosion resistance of the castable.

3. Application

The working lining of the main ditch is divided into iron line castable and slag line castable, and the gradient of the main ditch is properly adjusted to slow down the scouring of molten iron on the iron ditch. After adjustment of the construction scheme and improvement of materials, it was applied to a 1080m3 low silicon iron making blast furnace iron trench in Inner Mongolia. After use, the problem that the slag iron line erosion of the conventional iron trench castable is not synchronous and the contact part has grooves is improved, and the one-time iron flux is increased from 100000 t to 150000 t.

4. Conclusion

On the basis of the proportion of castables in the original iron trench, the working lining of the main trench is divided into iron wire castables with 10% (W) 15 ~ 8mm fused dense corundum and 4% (W) β- The slag line castable of Si3N4 Powder and the gradient of the main ditch are properly adjusted. After its application in the blast furnace iron ditch of low silicon iron making, the problems of accelerated erosion and intensified scouring of the slag and iron line in the main ditch are greatly improved.