15358968703

Common continuous casting equipment

Common continuous casting equipment

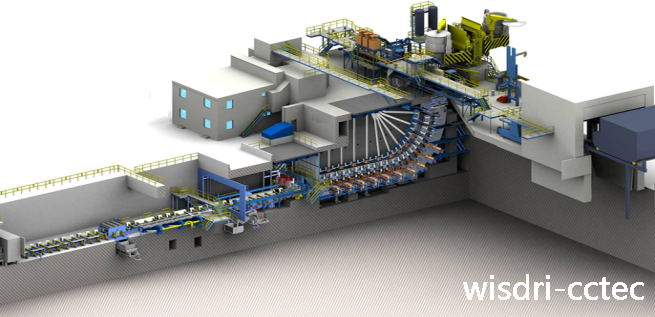

Overall effect drawing of billet caster

Overall effect drawing of slab caster

1) Ladle turret

Ladle turntable is used to turn the ladle to or out of the pouring position, mainly including straight arm type and butterfly type.

2) Intermediate tank car

The tundish truck carries the tundish filled with molten steel and runs between the set pouring position and baking position to realize the lifting, centering and weighing functions of the tundish.

3) Crystallizer

The crystallizer can rapidly cool the molten steel poured into it, and preliminarily condense and form according to the required section. Ensure that the shell of molten steel after the mold is out of the mold can withstand the static pressure of the internal molten steel that has not yet solidified.

Thermally adjusted slab crystallizer

4) Crystallizer vibrating device

The relative movement between the mold copper tube and the solidified shell of the casting slab is maintained, so that a good demoulding state and cooling and heat transfer effect are maintained between them. Mainly mechanical, hydraulic and electric cylinder vibration is widely used.

Hydraulic vibration of slab full leaf spring

Vibration of square billet electric cylinder

5) Sector (guide section)

The slab with liquid core comes out of the mold and enters the sector section (guide section), which is supported and guided by the sector section (guide section) roller and gradually solidifies.

Slab bending section

Slab segment

Bloom guide section

6) Tension leveler

It is used to transport dummy bar, pull dummy bar and hot billet from crystallizer, and straighten hot billet according to minimum critical stress. After the slab enters the horizontal section, it is cut to length by the fire cutter or hydraulic shear, and then transported to the discharge roller table by the cut roller table.

Integral tension leveler

Independent arch tension leveler