15358968703

Zhanjiang iron and steel 5050m 3 Configuration of refractory bricks for blast furnace tuyere area and area above tuyere

5050m at Zhanjiang iron and steel ³ The refractory materials for the tuyere area and above the tuyere area of the blast furnace are as follows:

1.Tuyere area tuyere

area is subject to the scouring of liquid slag iron and high air temperature, which is one of the limiting links of blast furnace longevity. In order to ensure the safe operation of the blast furnace, the refractory in the damper area must be kept at a certain thickness for a long time. Therefore, the refractory in the tuyere area is required to have very superior performance.

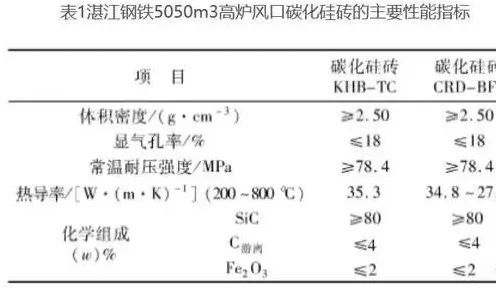

Zhanjiang iron and steel 5050m ³ The refractory materials in the blast furnace tuyere area are made of silicon carbide composite bricks produced by Japan's kurazaki seedmill. The brick has good volume and structural stability, superior thermal conductivity and slag iron corrosion resistance, and maintains good service conditions under long-term high load service conditions. In order to ensure the masonry quality, the standard formwork shall be made according to the assembly accuracy after the pre assembly of silicon carbide composite bricks in the manufacturer is qualified for on-site guidance. See Table 1 for the main performance indexes of the carbonized self composite brick for the tuyere.

2.Area above tuyere

The bosh, bosh and lower part of the furnace body above the tuyere are the key positions for the reaction of iron making materials. There are not only the abrasion of lining materials caused by the decline of various iron making materials, the scouring of lining materials by hot gas flow against the material flow, the erosion of lining caused by harmful components during the material reaction, but also the burning loss of furnace lining caused by molten materials. With the progress of blast furnace smelting production, the heat load The temperature changes very strongly. High intensity thermal scouring and large temperature fluctuation have a great impact on the furnace lining, and its destructive force and speed even exceed the chemical erosion. Therefore, as the refractory of the blast furnace shaft, only if it has the ability to withstand this kind of thermal shock, can it obtain a long service life. Zhanjiang iron and steel 5050m ³ Silicon nitride bonded silicon carbide bricks with high strength and good chemical corrosion resistance are selected at the furnace belly of the blast furnace, dense clay bricks are built at the furnace waist and lower part of the furnace body, and silicon nitride bonded silicon carbide materials are embedded in the cooling staves at the middle and upper part of the furnace body.

It can be seen from the above text that Zhanjiang iron and steel 5050m ³ Silicon nitride bonded silicon carbide bricks made in Japan are used in the tuyere area of the blast furnace. With the continuous improvement of production process and technology of domestic refractory manufacturers, the service performance of silicon nitride bonded silicon carbide bricks produced in China has far exceeded that of foreign countries.