15358968703

Discussion on current situation and control measures of zinc load in blast furnace of Xinsteel

Abstract: Based on the analysis of the raw fuel and incoming iron of Xingang blast furnace, it is clear that the main sources of zinc in Xingang blast furnace are converter sludge, Daying ore and purchased pellets, and the fuel brings less zinc, accounting for only 1%~1.5% According to the statistics and analysis of cross temperature measurement of 6 #, 10 # blast furnaces with high zinc load and good furnace condition straightness and indicators, as well as 11 # blast furnaces with poor indicators due to the thickening of the upper part of the furnace body, strengthening the central air flow of the blast furnace and increasing the central temperature can effectively reduce the zinc circulation in the blast furnace and reduce the zinc damage. The zinc content of the blast furnace bag ash can objectively reflect the strength of the central air flow of the blast furnace, and the blast furnace slag discharges less zinc, accounting for 1%~2% of the zinc in the furnace

Key words: blast furnace, zinc load, raw material source, control measures

Zinc in blast furnace raw materials usually enters blast furnace Sichuan as oxides or sulfides. During blast furnace smelting, its sulfides are first converted into complex oxides and reduced to Zn at a high temperature of not less than 1000 ℃. The reduced Zn is gasified and mixed into gas. During the rising process, some of it escapes out of the furnace with the gas, some of it condenses into solid state and returns to the furnace charge, a small amount of it agglomerates in the pipeline, and some of it is oxidized to ZnO and absorbed by the furnace charge for reduction again, Form a cycle 2 The main hazards are as follows: ① after entering the ore or coke and being oxidized to ZnO, the internal stress will be generated due to volume expansion, which will reduce the strength of ore and coke and increase the pulverization index of pellet and sinter; ② With the rise of gas, the pores of ore and coke are blocked and the permeability of charge is deteriorated; ③ Infiltrate into the crevice of the furnace lining refractory, condense and oxidize with the decrease of temperature to form ZnO volume expansion, destroy the refractory structure, and accelerate the erosion of the furnace lining; ④ Zinc vapor oxidizes and condenses in the throat, body and other parts of the furnace, bonding dust and forming furnace nodules [3-7] With the improvement of the steel market, the increased use of scrap steel has led to the increase of zinc content in converter sludge, and the increased pressure on environmental protection has made it difficult to export blast furnace bag ash. Since 2017, the zinc load of Xingang blast furnace has increased year by year, resulting in the thickening of blast furnace wall and the increase of fuel consumption, especially the serious thickening of the upper part of 11 # blast furnace body. In order to alleviate the impact of zinc on blast furnace production, this paper discusses the current situation of zinc load of Xingang blast furnace The source and control measures are discussed in order to reduce the zinc damage of blast furnace

1. Current situation and source of zinc load in blast furnace of Xingang

1.1 current situation of zinc load of blast furnace at Xinsteel

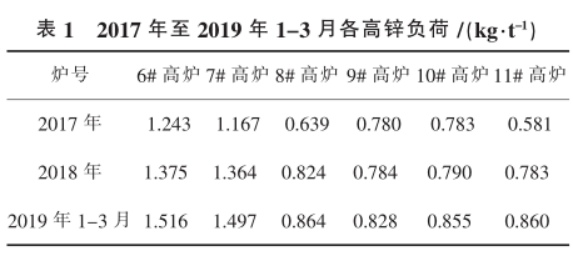

With the improvement of the steel market, the use of scrap steel, especially cold rolled briquettes with high zinc content, the increase of zinc content in converter sludge, and the impact of environmental factors have made it difficult to export sack ash, which has increased the zinc load of blast furnace of Xinyu Iron and Steel Co., Ltd. year by year. See Table 1 for details

1.2 analysis of zinc source of blast furnace

Through the analysis of the zinc content of blast furnace materials and raw fuels of Xingang from January to March 2019, the raw fuels of blast furnace are mainly from sinter, and the higher the zinc load is, the larger the proportion is, followed by pellet, and the proportion of zinc brought by fuel is small, accounting for only 1%~1.5%, as shown in table 2

1.3 source analysis of iron and zinc

In order to understand the zinc source of new iron and steel materials, the quantity and zinc content of incoming iron materials from January to March 2019 are analyzed, as shown in table 3 The circulating materials produced by blast furnace, such as dust removal ash and gas ash, have been included in the calculation of iron charge and are not considered in the analysis Converter sludge and Dading ore contain high zinc, which has a great impact on the source of zinc, and will be calculated separately According to the calculation results, the amount of converter sludge and Dading ore only accounts for 4.88%, and the zinc brought into the iron material accounts for 50.27%, especially the zinc brought into the converter sludge accounts for 35.32% Purchased pellets are also one of the important sources of zinc, accounting for only 3.59% of the purchased amount and 8.46% of the imported zinc. The main reason is that the zinc content of Jinzhu pellets reaches 0.136%, which is far higher than the average zinc content of self-produced pellets by 0.06% The imported ore brought in less zinc, accounting for 72.28%, and zinc only accounted for 14.59% Therefore, reducing the zinc content of converter sludge, controlling the use of cold rolled briquettes with high zinc content, and controlling the use of Dading ore and purchased pellets with high zinc content can effectively reduce the source of zinc

2. Analysis of influencing factors of zinc discharge from blast furnace

The zinc discharged from blast furnace is mainly discharged with gas through gravity ash and bag ash, as well as through slag, iron and dedusting in the cast yard The gravity ash of the blast furnace and the dedusting ash of the cast house of Xingang are sent to the sintering plant for use, and the bag ash of the blast furnace is sold out in a unified way. The composition of the bag ash of the blast furnace is not tested and measured separately, and the zinc content of the iron and slag is not tested, so it is difficult to analyze the zinc balance of the blast furnace. In this paper, only the qualitative analysis of the influencing factors is carried out The blast furnace of Xingang iron and Steel Co. Ltd. adopts molten iron classification smelting to meet the production needs of variety materials. Among them, the requirements for molten iron quality of 6 #, 7 # blast furnaces are low, the proportion of secondary resources such as circulating materials is high, and the zinc load is high

In recent years, with the increasing pressure of environmental protection, it is difficult to export cloth bags, and the use of scrap steel increases, resulting in the zinc load of blast furnace increasing year by year In order to understand the influence of gas flow distribution and slag on zinc discharge, the 6 # and 10 # blast furnaces with good technical and economic indicators and less affected by zinc damage and the 11 # blast furnaces with greater affected by zinc damage are selected for comparative analysis

2.1 influence of slag

The reduction reaction of zinc in slag is shown in equation (1) 89 Znsio3+2cao+2c=zn (g) + 2CaO · sio2+2c0 (1) after the basicity increases, the amount of free CaO in the slag increases, which promotes the reduction reaction. Therefore, reducing the basicity of the slag is conducive to improving the zinc removal capacity of the blast furnace slag Taking 6 #, 11 #, 10 # blast furnace slag for detection, the zinc content is 0.003%, 0.004%, 0.003% respectively, and the zinc brought out only accounts for 1%~2% of the zinc into the blast furnace. Therefore, it is not advisable to reduce the circulation of zinc in the blast furnace by increasing the zinc discharge of the slag. Moreover, the low basicity of the slag will reduce the heat consistency of the slag, reduce the hearth temperature, affect the smooth operation of the furnace, reduce the desulfurization capacity of the slag, and affect the quality of molten iron

2.2 influence of blast furnace gas distribution

The circulation process of zinc in the blast furnace: the reaction in the high-temperature area around 1000 ℃ is as equation (2), and the reaction in the low-temperature area around 580 ℃ is as equation (3) ZnO+CO=Zn+CO2 (2)Zn+CO2=ZnO+CO (3)

Due to the high temperature and fast flow rate in the center of the blast furnace gas flow, there are few opportunities for zinc to solidify again. A strong central gas flow can bring zinc into the gas in a short time, Instead of being re solidified and falling back into the furnace charge (8.91 the edge air flow is affected by the cooling of the furnace wall, the temperature decreases quickly and the flow rate is slower than the center, and the zinc oxide is easy to bond to the furnace wall, so the zinc oxide causes the furnace wall to thicken, and the focus is on the upper part of the furnace body. Therefore, in order to increase the discharge of zinc from the coal gas on the top of the furnace, it is necessary to moderately release the center air flow, control the edge air flow, and reduce the accumulation of zinc in the furnace

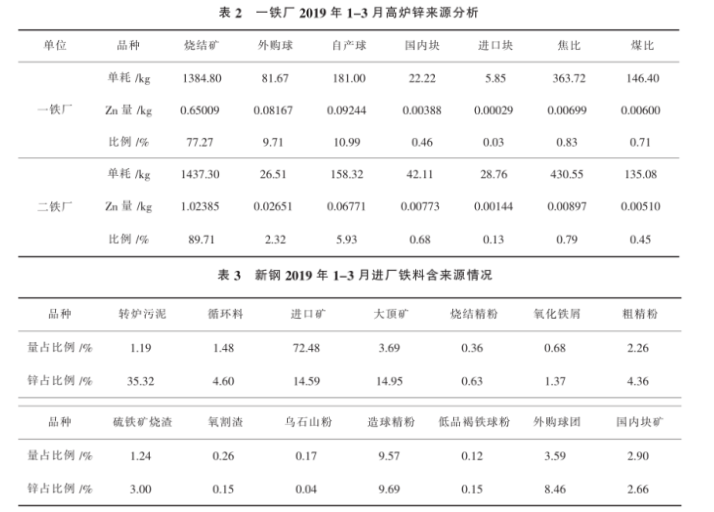

2.2.1 top temperature of 6 #, 10 # blast furnace

Xingang 6# blast furnace was overhauled and put into operation in August 2017, with an effective volume of 1050m3; 10 × blast furnace was completed and put into operation in November 2009, with an effective volume of 2500m3 The zinc load of the two blast furnaces is high and the difference is large. Although there are phenomena such as furnace wall thickening and slag skin falling off, on the whole, the furnace condition has been smooth in recent years, especially the technical and economic indicators of 10 # blast furnace are at the advanced level of the industry. See Table 4 for details

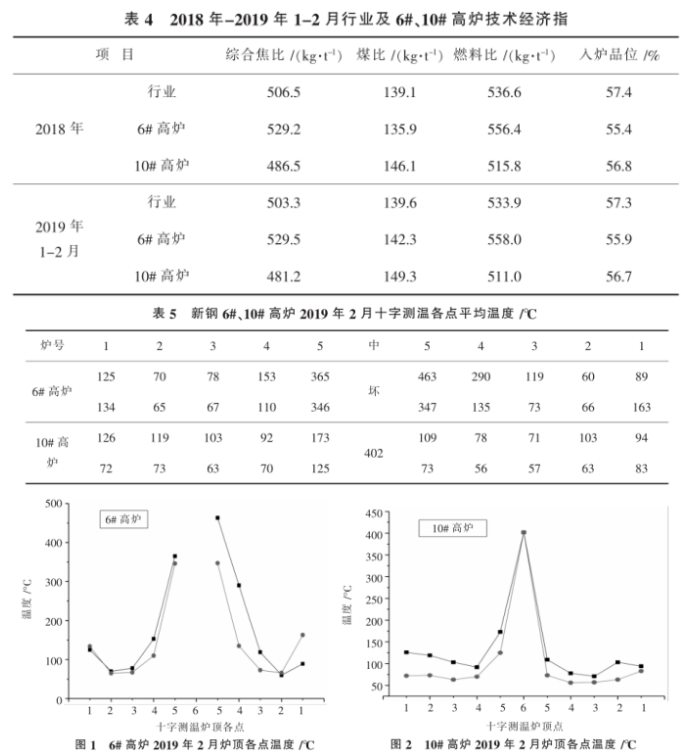

It can be seen from table 4 that the impact of zinc damage on 6 #, 10 # blast furnaces is relatively light, and there is no serious zinc enrichment, indicating that the inlet and outlet of zinc in blast furnaces have basically reached a balance See Table 5 for the average temperature of each point of cross temperature measurement on the furnace top in February 2019 and make a curve, as shown in Figure 1 and Figure 2 The gas distribution of the two blast furnaces is in a central development shape. The average temperature measurement point of the 10 # blast furnace center is 402 ℃, the average temperature of the fifth point is 120 ℃, and the average temperature of the first point is 94 ℃. The temperature measurement point of the 6 # blast furnace center is bad, the average temperature of the fifth point is 380 ℃, and the average temperature of the first point is 124 ℃. The temperature and range of the gas flow center are far higher than that of the 10 # blast furnace. Although the zinc load is high, the zinc discharge capacity is strong Therefore, during the operation of the blast furnace, the coke distribution in the center of the charge column should be appropriately increased with the increase of the zinc load of the charge, the average temperature of the center and the fifth point should be increased, and the zinc circulation and enrichment in the blast furnace should be reduced

2.2.2 11# blast furnace top temperature

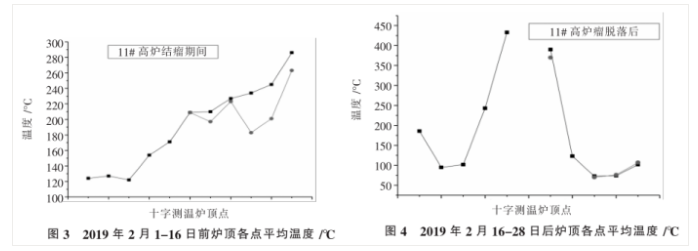

Xingang 11# blast furnace was completed and put into operation in December 2011, with an effective volume of 1050m3. Before 2017, the zinc load was lower than 6# and 10# blast furnaces, which began to rise in 2018, and is now slightly higher than 10# blast furnaces The central air flow of the blast furnace is weak for a long time, and the enrichment of zinc in the blast furnace causes serious local thickening in the upper part of the furnace shaft. The technical and economic indicators of the blast furnace are poor, and the fuel consumption is about 20kg/t higher than that of other 1050m3 blast furnaces On February 16, 2019, most of the thickened materials fell off, the smoothness of the furnace condition improved, and the gas flow distribution changed significantly It can be seen from Figure 3 that during thickening, the gas flow deviates seriously, and the central temperature is about 200 ℃. Although the zinc load is lower than that of other blast furnaces, it is enriched seriously. The upper part of the blast furnace shaft is seriously thickened, and the zinc content of bag ash is only 2%~3% On the 17th and 28th, due to the falling off of furnace lump, the smoothness of furnace condition improved, as shown in Figure 4 The distribution of gas flow shows a central development shape, and the zinc content of bag ash rises to 4% 0~5%

2.2.3 relationship between zinc content in bag ash and gas distribution

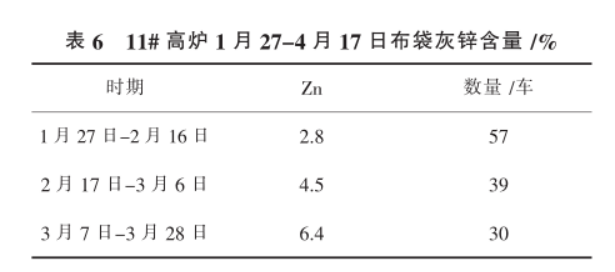

The finer the dust in blast furnace gas, the larger the specific surface area, and the stronger the adsorption capacity of zinc oxide. Therefore, the zinc content of blast furnace bag ash is much higher than that of gravity dust removal ash The higher the zinc content of the bag ash, the greater the discharge of zinc from the blast furnace and the less zinc is enriched in the furnace. Therefore, the distribution of blast furnace gas can be judged by the zinc content of the bag ash If the blast furnace central air flow is strong, the bag ash content is higher, and if the zinc content is low, the central air flow is weak The distribution of gas flow is reasonable, the smoothness of furnace condition is good, and the blowing out of furnace dust is relatively reduced. The distribution of gas is disordered, the smoothness of furnace condition is poor, and the blowing out of furnace dust is large Xingang blast furnace sack ash is sold as takeaway without zinc detection. In recent years, due to the increased pressure of environmental protection, the zinc content is low. 11 # blast furnace sack ash is transferred to the sintering plant for use. On January 27, a routine analysis of 11 # blast furnace sack ash is carried out every day. The zinc content detection data from January 27 to March 28 are taken, and the statistics are based on a cycle of 20 days. See Table 6. From January 27 to February 16, due to the weak central air flow and unstable gas flow, the amount of sack ash is large and the zinc content is low After February 17, due to the falling off of local thicknesses and the enhancement of central gas, the zinc content of bag ash gradually increased and decreased

2.3 effect of blast furnace zinc load on fuel consumption

According to the oxidation and reduction mechanism of zinc in the blast furnace, the burn up of the blast furnace increases with the increase of zinc load in the furnace. ① Zn0 is reduced to Zn by CO in the high temperature zone above 1000 ℃, consuming the conno in the lower high temperature zone; ② With the increase of zinc load in blast furnace, the temperature and range of central gas flow need to be increased to reduce the circulation and enrichment of zinc in blast furnace; ③ The gas distribution is seriously affected by worsening the permeability of the feed column and causing the furnace wall to nodulate and thicken

3. Conclusion

1) Sinter is the main source of zinc in the blast furnace burden of Xingang. The higher the zinc load, the greater the proportion of zinc brought in by sinter, and the zinc brought in by fuel only accounts for 1%~1.5%

2) The amount of converter sludge, Dading ore and purchased pellets at Xinsteel accounts for 8.47% of the iron material, and the amount of zinc brought into the iron material accounts for 58.73%. In particular, the amount of converter sludge only accounts for 1.19% of the iron material, while the amount of zinc brought in reaches 35.32% Only by controlling the amount of converter sludge, zinc content in purchased pellets and the use of Dading ore, can the zinc load of Xingang blast furnace be effectively controlled

3) Although reducing the basicity of slag can increase the discharge proportion of zinc, low basicity slag will reduce the hearth temperature, affect the smooth operation of furnace conditions and the quality of molten iron, and its discharge of zinc only accounts for 1%~2% of the zinc in the furnace. Therefore, reducing the basicity is not desirable

4) Only by increasing the central temperature of blast furnace gas and strengthening the central dominant air flow can the discharge of zinc be effectively increased (9), the circulation and enrichment of zinc in the blast furnace be reduced, and the harm of zinc be reduced With the increase of zinc load of blast furnace, the coke distribution in the center of charge column should be increased and the average temperature at the center and point 5 should be increased during the operation of blast furnace

5) The zinc content of bag ash and the weight change in unit time can judge the strength and stability of the central gas flow of the blast furnace. The increase and decrease of zinc content indicate that the central gas flow is enhanced and the stability is improved. Therefore, bag ash should be included in daily routine inspection