Senjimir twenty high cold rolling mill

The essential difference between Senkimir cold rolling mill and four-high rolling mill or other types of rolling mill is that the direction of transmission of rolling force is different. The rolling force of the Senkimir cold mill is transmitted from the work roll through the intermediate roll to the support roll device and finally to the solid integral frame. This design ensures that the work roll is supported in the entire length direction. In this way, the deformation of the roll system is minimal, and very accurate thickness deviation can be obtained in the entire width direction of the rolling.

(1) The frame with integral casting (or forging) has large stiffness, and the rolling force acts radially on various sections of the frame.

(2) The working roller diameter is small, and the pass reduction rate is large, up to 60%. Some materials can be rolled into very thin strips without intermediate annealing.

(3) With axial and radial roll shape adjustment, roll diameter size compensation, rolling line adjustment and other mechanisms, and the use of hydraulic pressure and hydraulic AGC system, so the product shape is good, high dimensional accuracy.

(4) The weight of the equipment is light, and the quality of the mill is only one third of the four-roll mill of the same specification. The rolling mill is small in size and requires less capital investment.

Senjimir cold rolling machine is basically a single stand reversible arrangement, flexibility, wide product range. However, there are also very few Senjimir rolling mills in continuous arrangement, such as a set of 1270mm four-stand fully continuous 20-high Senjimir rolling mill designed and manufactured by Japan Senjimir Company in 1969 for the Zhunan plant of Japan Nissin Steel Company. The first mill is ZR22-50" type mill, the other three are ZR21-50" type mill, rolling specification is O.3mm×1270mm stainless steel, roll weight is 22t, rolling speed is 600m/min.

The form and nomenclature of Senkimir cold rolling mill are described below:

The most commonly used form of Senkimir cold mill is the 1-2-3-4 type 20-high mill. For example, ZR33-18 ", "Z" is the first letter of the Polish word Zimna, meaning" cold "; "R" stands for "reversible"; "33" indicates the model of the mill; "18" is the number of inches of the width of the rolled strip. The Senkimire cold mill also had a 1-2-3 12-high mill, but the 1-2-3 Senkimire cold mill was no longer manufactured after 1964.

Sengemil cold rolling mill Type 1-2 six high mill, consisting of 2 driven work rolls and 4 backing roller units, such as ZS06, "S" for "sheet", used to roll wide sheets, but it can also roll strips, and some are also used in continuous processing lines.

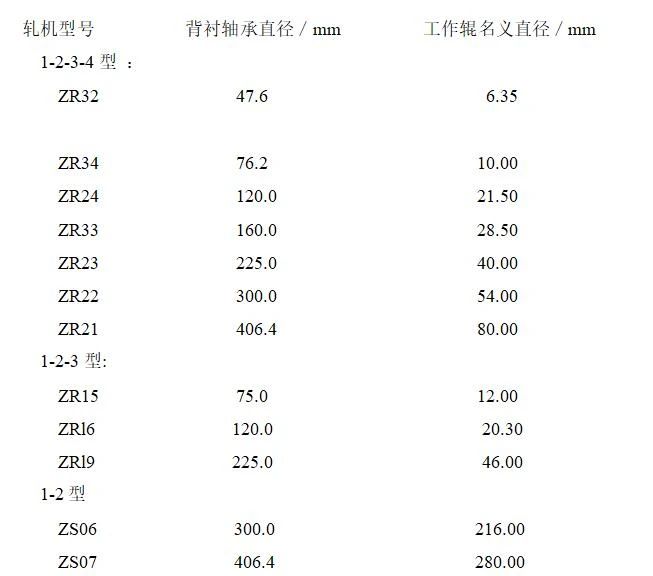

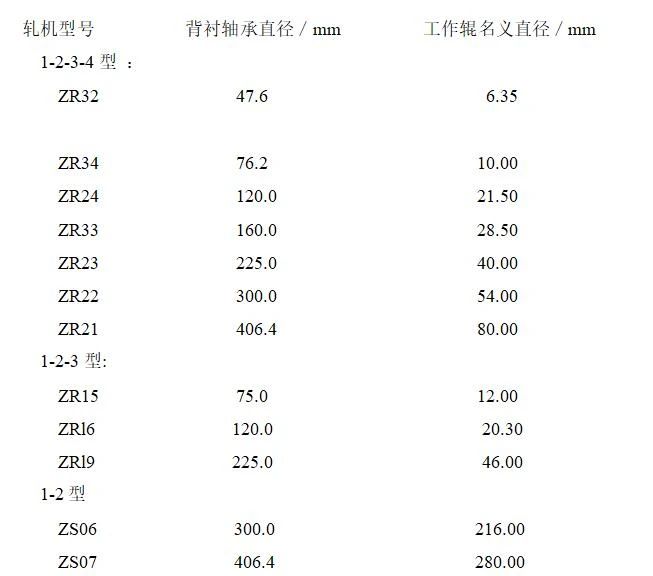

Senkimir "ZR" type cold rolling mill has 10 basic models, including 1-2-3-4 20-high mill 7; 1-2-3. Type 12 high mill 3; The "ZS" Type 1-2 six-high mill is available in only 2 basic models. The outer diameter of the backing bearing and the nominal diameter of the work roll of each type of rolling mill are as follows:

On the basis of the above basic models, some special models are derived, and the letters of different meanings are added to the end and beginning of the basic model.

The basic model is the basic design of the Sengemil cold mill, and the geometry of the roll arrangement provides the mill with the minimum diameter of the work roll. The derived model is essentially based on the change of work roll diameter and mill opening degree.

ZR21A: A single "A" appears only in the ZR21A, indicating that the work roll diameter of the mill is 66 to 76mm, which is smaller than the work roll diameter of the basic model ZR21.

ZR21AA: "AA" only appears in the ZR21AA, it indicates that the mill's quince hole position, the size of the middle roll is completely different from the basic model, and the eccentricity is also greater than the basic model. Therefore, the work roll diameter of the mill is smaller than that of the ZR21A.

ZR21B, ZR22B, ZR23B, ZR33B, ZS07B: A single "B" indicates that the vertical distance of the mill bore is slightly larger than that of the basic model, allowing for a slightly larger work roll diameter, while all intermediate rolls are the same size as the basic model.

ZR21BB: "Boat" indicates that the mill has the same hole position and roll size as a single "B" mill, except that the eccentricity is increased so that the opening of the work roll can be increased.

ZR23C, ZR33C: A single "C" indicates that AS-U-ROLL roll shape adjustment devices are designed in the "B" and "C" rollers of the mill. Previously, only rolls "A" and "D" of this model had manual roll shape adjustment devices, or not.

ZR23M: "M" indicates that the mill has a particularly large work roll with a different mux hole position than the basic model. The mill is beneficial to the rolling of non-ferrous metals.

ZR23D: The additional change in roll diameter is not covered by the A, B, M type, and its diameter is between the B and M type mills.

ZR21MB: "MB" indicates that the mill has a particularly large work roll which is different from the basic type in the plum bore position; In addition, the eccentricity adjustment of the side is increased compared with the basic type in order to obtain a larger roll range.

ZR22N: "N" indicates that the mill has a larger work roll for a particular purpose.

ZR22S: The "S" indicates that the distance of the quince-hole of the mill and the size of all rolls are larger than that of the basic mill so that the smallest roll of the "S" mill can be used by the basic mill.

ZR33W: The "W" indicates that the mill offers specially designed AS-U-ROLL shape control for rolling strips with strict wedge requirements.

ZR33CW, ZR23SC: This two-letter combination usually indicates the combination of these two single-letter models.

At present, the development level of Senjimir mill is as follows:

(1) Maximum width of rolled strip. At present, the widest rolling strip is a French ZR22-80 mill, rolling a maximum width of 2032mm of mild steel and silicon steel, thickness deviation of ±0.005mm.

(2) Minimum thickness of rolled strip. The minimum thickness of rolled strip is related to its width and steel grade. The minimum thickness of rolled silicon steel in the United States is 0.002mm, and its width is 120mm. Japan rolled stainless steel, when the width is 1220mm, the minimum thickness is 0.127mm; When the width is 200mm, the minimum thickness is 0.01mm; When rolling non-ferrous metals, the thinest can reach 0.0018mm(ZR32-4 1/4 type, rolled copper).

(3) Rolling speed. The maximum speed of low carbon steel rolling by ZR21-44 mill in America is 1067m/min. America, Japan and other countries rolling silicon steel and stainless steel ZR21 mill rolling speed up to 800m/min.

A complete set of twenty high Sengimil mill, generally including the mill working stand, coiler, uncoiler and feeding mechanism, AGC system, hydraulic system, cooling system, exhaust smoke system and other parts.