15358968703

Analysis on bearing damage of 650 cold rolling mill

Bearing model: fcd76108400/p6c3

Application position: support roll;

Lubrication type: oil air lubrication;

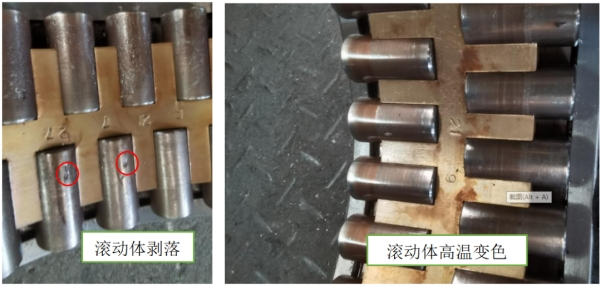

Bearing damage form: the rolling element peels off and the color changes seriously (as shown in the following figure);

The quantity of this supply is 10 sets in a batch, which is mainly aimed at solving the problems of early bearing cage damage, deformation and tooth loss in a short time (about 30 days), outer ring damage, fragmentation and spalling, inner ring channel sinking, rolling element spalling and falling off, etc.

After 2 months of operation, the results show that the use effect of inner ring, outer ring and cage has been better improved, but the surface of the three sets of rolling elements has peeled off. Through summary and analysis again, it is considered that the main reasons are as follows:

1. Insufficient oil under damaged bearing

The bearing of the equipment is small in type selection, and the bearing is relatively loaded with a large working load. The internal load area of the bearing is relatively sensitive to the requirements for lubrication effect. Once there is poor oil or little oil, it is very easy to cause the lubricating oil film in the load area to break, resulting in metal friction between the bearing rolling element and the inner and outer rings. Because the rolling element has the smallest diameter relative to the inner and outer rings, and the self transmission speed is high, the oil volume is too small, resulting in high temperature on its surface, This will cause discoloration and fatigue spalling.

2. Objective bump and scratch

At present, the bearings are installed by crane, so it is inevitable that there will be objective bumps and scratches during installation. The bearing clearance of this batch is group C3, with a radial clearance of 0.28-0.37mm, a journal size of Φ 380 (+0.14 +0.10), an inner diameter of Φ 380 (0 -0.025) of the bearing inner ring. After installation, the inner ring and the shaft have interference. After installation, the minimum radial clearance of the bearing is 0.12. During installation, the special clearance has installation scratches, which are mainly on the surface of the rolling element, Under the action of high load, it expands into spalling.

3. Sealing problem of lower roll

At present, when the lower roll system is installed, the two oil seal lips of the bearing box are facing inward, mainly to prevent oil and gas leakage in the bearing box and lip turning during installation. After the roll system is sleeved, there is a gap of about 5mm, as shown in the following figure:

When the machine is running, the coolant enters around the sealing ring through the gap. Since the lip of the sealing ring is inward, the waterproof effect will be poor. The coolant will enter the bearing and erode the bearing.

Corresponding adjustment measures:

1. In terms of bearing, the radial clearance of bearing shall be adjusted to 0.35-0.37mm to increase the installation clearance and reduce the collision during installation; 2. Oil quantity problem, especially at the drive side of the lower roll, please check the oil and gas plug and oil pipe to ensure that there is no damage and air leakage problem, and ensure the oil and gas supply of the bearing. If the lower oil quantity is found to be small, record the installation and use position of the bearing, take pictures, keep files, and report in time; 3. For the sealing problem of lower roll, water was added to seal and labyrinth circuit to prevent excessive emulsion from directly washing the gap of roll system;