15358968703

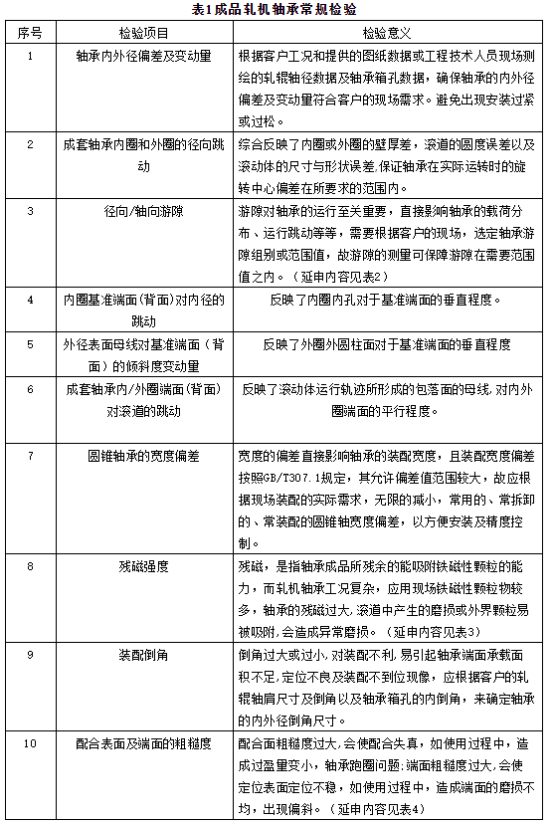

10 routine inspections of finished rolling mill bearings and their significance

As an important component of the rolling mill roll system, especially the rolling mill bearings of the plate, strip and foil cold rolling mill roll system, due to the high-speed development of the rolling mill towards high-speed, high-yield and the high-quality and high-precision of the rolled products, the configured rolling mill bearings also need to be improved accordingly, especially the dimensional tolerance of the bearings listed in the table below and the routine inspection of other items, It is of positive significance to the overall accuracy and operation stability of the bearing.

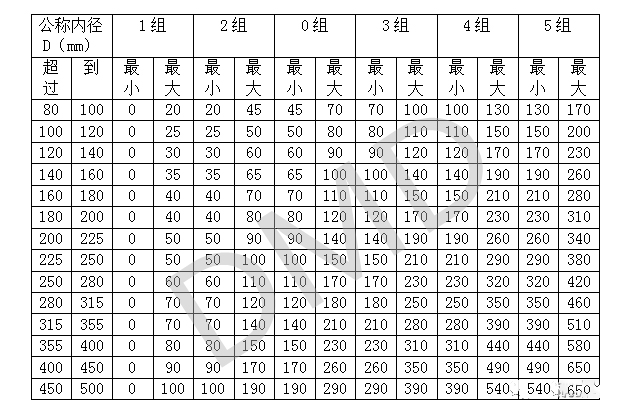

Extension of No. 3 clearance: bearing clearance refers to the clearance between the bearing rolling element and the inner and outer rings of the bearing, that is, when the bearing is not installed on the shaft or bearing housing, fix one side of its inner ring or outer ring, and then make the unfixed side of the bearing move radially or axially. According to the moving direction, it can be divided into: radial clearance and axial clearance; according to the state, it can be divided into: original clearance; Installation clearance; Running clearance, here is a list of requirements for clearance range of double row or four row tapered bearings:

Table 2 radial clearance of double row or four row tapered bearings unit: Um

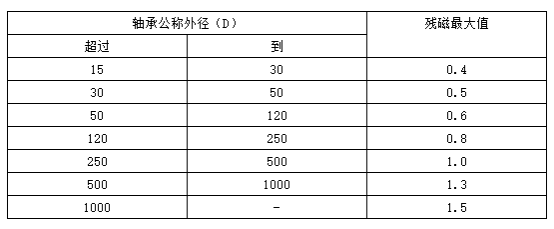

Note: the radial clearance is converted to the general value of axial clearance (ga=crx1.5/e; GR radial clearance value, e coefficient, see the bearing dimension table DMD technical sample book) s / N 8 residual magnetism content extension: residual magnetism refers to the maximum residual magnetism of the bearing that has been magnetized during production and has not been eliminated after demagnetization. The residual magnetism is expressed by the physical quantity of magnetic induction intensity, and its unit is millitex (MT). The residual magnetism is inspected by sampling acceptance method, The sampling number shall be in accordance with the provisions of jb/3371. The acceptable quality level AQL shall be taken as 4, the general inspection level shall be sampled, and the Hall effect principle shall be used for measurement. Since most of the bearing processing workers now use electromagnetic chuck for clamping, although the bearing parts undergo the demagnetization process of the machine tool itself after precision machining, the residual magnetism still exists, so the demagnetization process after the machine is added. The residual magnetic field standard of finished bearing shall comply with the specified value in jb/t6641-2017:

Table 3 limit value of bearing residual magnetism unit: MT

No. 10 extension of roughness of mating surface and end face:

Table 4 roughness of mating surface