15358968703

What changes does "5g+" bring? Upgrading of "intelligent manufacturing" from Xianggang

Strengthening the power, computing power and the power support represented by scientific and technological innovation is a practical action to comprehensively implement the strategic positioning and mission of "three highs and four innovations", and a landmark project to enhance the long-term competitiveness of Hunan Province. Among the "three supports", computing power determines the future. Recently, the general office of the Hunan Provincial People's government issued the "plan for strengthening the" three forces "support in Hunan Province (2022-2025)", proposing that by the end of the "fourteenth five year plan", the computing support capacity will be greatly improved, and strive to achieve the national leading communication network infrastructure and the central leading data and computing facilities.

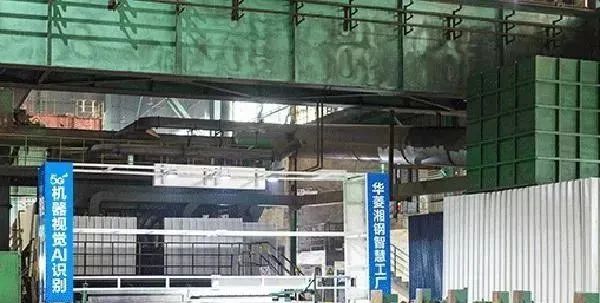

Xianggang 5m wide and thick plate plant

A 5g network connected patrol UAV is taking omni-directional photos around large blast furnaces and high-voltage power transmission lines, sending the infrared imaging video back to the monitoring platform for analysis, and automatically carrying out blast furnace wall temperature measurement, spot inspection of high-voltage lines and porcelain insulators.

The unmanned crown block carries out closed-loop control through high-definition cameras, sensors, rangefinders, etc., and accurately and efficiently sends the bars to the designated position according to the delivery time and length of the products.

The staff wear ar glasses, realize remote technical support through 5g network, and realize transnational equipment installation and commissioning.

Xiangtan Iron and Steel Group Co., Ltd., as the benchmark of China's iron and steel industry, has in recent years seized the time window for the rapid development of 5g new infrastructure, accelerated the pace of digital transformation and upgrading, and promoted the "5g+ intelligent manufacturing" application scenario to blossom everywhere in Xiangtan Iron and steel Co., Ltd., injecting surging power into the transformation of new and old kinetic energy and high-quality development.

Intelligent control center of Xianggang 5m wide and thick plate plant

"5g+" magic creates a smart factory

At Xiangtan Iron and Steel Co., Ltd., there are many giant cranes used to transport molten steel, molten iron and other production materials. In the past, the conditions of the workers operating the crown block were difficult. It took half an hour each time to climb the crown block operation room 10 stories high and cooperate with the operation through the signals sent by the ground commanders. Now, workers can control the crown block in real time and from multiple perspectives in the central control room.

"We have applied 5g and industrial Internet technology to the crown block. Through a small joystick, workers can realize the remote control of steelmaking, rolling, finished products, warehousing and other processes, and liberate steel workers from the high temperature, noisy and high risk working environment." In 2019, Xiangtan Iron and Steel Co., Ltd. closely followed the digital development wave and joined hands with China Mobile and Huawei to jointly build a 5g smart factory in Xiangtan Iron and Steel Co., Ltd.'s 5m wide and thick plate plant, making the traditional factory more "smart".

The 5g unmanned crown block is covered with 7 cameras to restore the entire working environment on site. Through high-definition cameras, combined with 5g network high-speed rate, 360 degree full coverage of the site is achieved. At the same time, through the 3D scanning imaging technology, the height of the loading bucket of the on-site logistics vehicle and some lifting information on the site can be transmitted to the control room in a high-definition manner at the first time to help the staff make accurate judgments and realize safe and efficient lifting operations.

5g slag adding manipulator, 5g ultra dense video return, 5g+ocr steel plate identification, 5g steel transfer automation, 5g scrap AI grading, bar surface AI quality inspection, Xianggang cloud platform... With more and more "5g+" application scenarios landing in Xianggang, 5g accelerates the development and application of Xianggang intelligent manufacturing with the trend of "magic black technology".

"5g+ machine vision AI recognition" system can quickly and automatically identify steel plate code

Integrating multiple application scenarios to increase benefits

At present, Xianggang has built 210 5g private network base stations, realizing full coverage of 5g private network in the plant. Through the empowerment of "5g+ intelligent manufacturing", Xianggang has completed the automatic transformation of manual operation posts with low value-added, pure duty, poor environment and low efficiency, and has incubated a series of innovative applications of steel production process by using "5g+ cloud +ai" and other new generation ICT technologies, opening a new process of digital intelligence transformation of new infrastructure of Xianggang.

The traditional grading of bulk scrap depends on the naked eyes of quality inspectors. The process is cumbersome and difficult to quantify and standardize. To this end, Xiangtan Iron and Steel Co., Ltd. has cooperated with China Mobile and Huawei in R & D, using 5g network, big data storage, AI cloud reasoning, edge computing, vehicle identification and positioning and other technologies to build a unified intelligent control platform and establish a massive database of physical pictures of bulk scrap. In the process of scrap unloading, the objects in the carriage are scanned and matched with the database through the high-definition intelligent spherical camera, and then the calculation function of the AI system is used to complete the processes of automatic grading and miscellaneous deduction.

The implementation of the project can realize 24-hour uninterrupted work, effectively improve the production efficiency and reduce the labor cost, and the grading of scrap steel is more objective and accurate. The annual economic benefit can reach 5million yuan.

According to the data, since 2016, Xianggang has approved 303 intelligent manufacturing projects, with a total investment of 560million yuan. It has gradually realized the centralization of plant operation, automation of equipment operation and unmanned high-risk posts. The labor production efficiency of Xianggang has increased by 254%, effectively reduced the operation cost, improved the product quality and process stability, and driven the annual direct economic benefit of 280million yuan.

In the future, Xianggang will continue to use ICT technologies such as "5g+ cloud +ai+ big data" to deeply integrate with iron and steel production, seamlessly open up the whole process of data collection, transmission, processing and application in the plant, realize the visualization, manageability and controllability of Xianggang 5g private network and application, help Xianggang achieve fundamental changes in business decision-making, production management, manufacturing execution and other processes and modes, and promote Xianggang to improve processes, improve efficiency and product quality, By the end of 2022, we will strive to achieve the goal of "reducing enterprise operating costs by 20%, shortening the R & D cycle of new products by 20%, improving production efficiency by 20%, reducing product defect rate by 10%, and improving energy efficiency by 5%".