15358968703

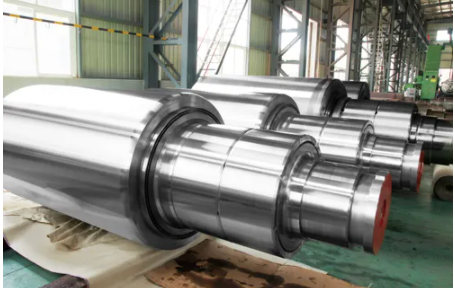

grooveless rolling

2022-06-23

The method of rolling billets and bars on flat rolls without grooves is also called flat roll rolling, round edge rectangular rolling or grooveless rolling. Square billet, square steel and round steel are generally roll...

Installation and adjustment of guide

2022-06-22

Adjustment of round steel and threaded guide: 1) Single line part 1. During the adjustment of all imported rolling guides, the guide roller of the guide must be consistent with the rolling center line of the guide...

High precision cold rolling strip shape control and equipment technology

2022-06-21

The research on "high precision cold rolled strip shape control and equipment technology" aims to develop and break through key technologies such as adaptive setting of strip shape target curve, multivariable optimi...

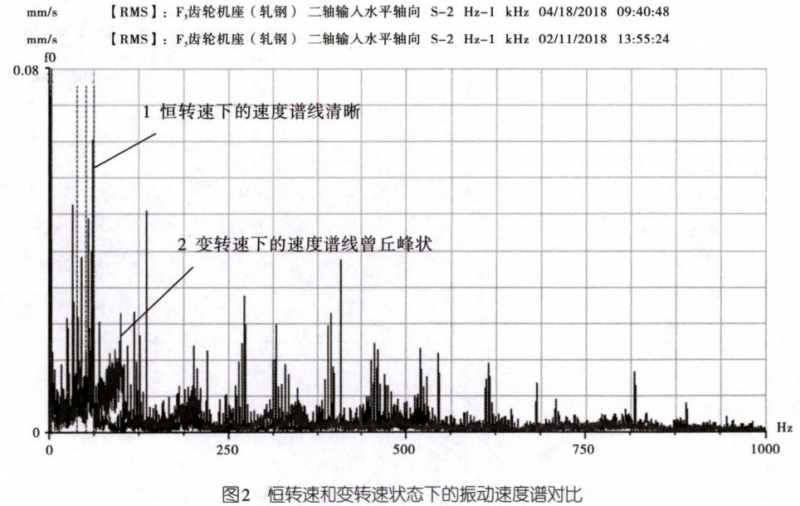

Design of on-line vibration monitoring and fault diagnosis for main drive of hot rolling finishing mill

2022-06-20

This paper describes the overall design, basic structure and data storage strategy of the on-line vibration monitoring and fault diagnosis system for the main drive of hot rolling finishing mill in Bayuquan branch of Angang. ...

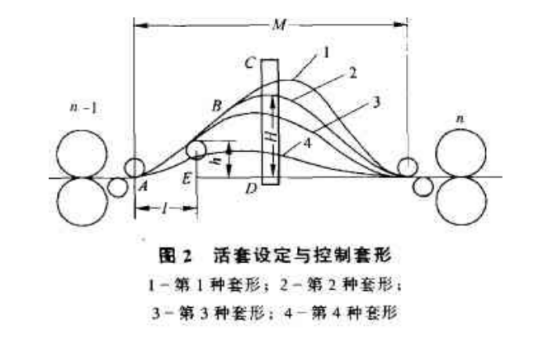

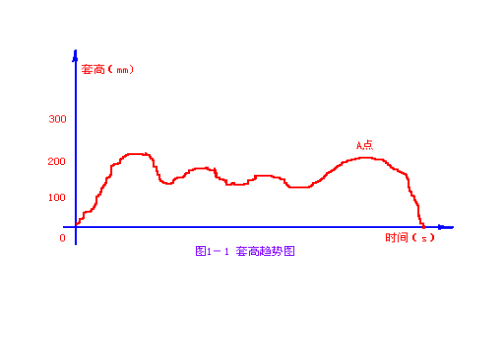

Basic knowledge of looper in high-speed wire mill

2022-06-17

Looper In order to ensure the dimensional accuracy of products, modern high-speed wire rod mill adopts micro tension and non tension rolling to eliminate the tension fluctuation caused by various dynamic disturbances in...

Control points of looper in rod and wire rolling

2022-06-16

Abstract: looper plays an important role in eliminating the tension between stands in the continuous rolling of rod and wire rod. Poor control of looper will not eliminate the tension, but will increase product defects and st...

Research on technology of reducing consumption and improving efficiency of rolling reheating furnace

2022-06-15

Heating furnace is an important thermal equipment in the production of iron and steel industry. It plays a very important role in steel rolling production. Its energy consumption accounts for 6% of the total energy consumptio...

Characteristics and working principle of six high mill

2022-06-14

The traditional four high mill is a technology in the field of plate and strip rolling. With the increasing requirements for plate accuracy and shape, especially for the dimensional accuracy of strip, the shape control abilit...

Cause analysis of iron oxide scale in steel rolling

2022-06-13

In the surface quality of hot rolled products, the pressing defect of iron oxide scale is a headache in the product quality of many factories. After pickling, the iron oxide scale pressed into the surface leaves small pits wi...

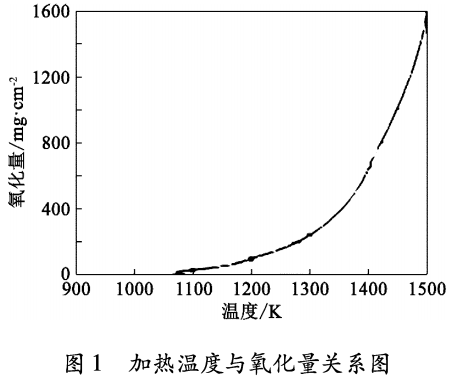

Discussion on oxidation of billet in heating furnace

2022-06-13

Abstract: in this paper, the mechanism, causes and influencing factors of iron oxide scale formation during + billet heating in the heating furnace are briefly discussed, and some measures and methods to reduce oxidation burn...

Causes and effects of iron oxide scale formation

2022-06-11

Iron oxide scale is a layer of metal oxide attached to the metal surface when the metal is heated, heat treated or processed in a hot state. Due to the difference of metal composition, surface temperature, heating and cooling...

Optimization of double length cutting program of flying shear and common fault treatment

2022-06-10

1. Basic functions and composition of flying shear In this rolling line, the flying shear is an important part of the auxiliary transmission equipment in the production line, which has a great impact on the normal produ...