15358968703

Surface quality defect analysis of hot rolled strip

2023-12-07

Abstract:With the development of information technology, the process and quality control platform will play an active role in the hot rolling production process. By combining data-driven algorithm and intelligent algorithm, thi...

Analysis and control of corrugation defects of cold rolled strip after leveling

2023-11-13

Abstract:This paper analyzes the causes of corrugation defects in the rolling process of annealed strip steel, introduces the measures of controlling the rolling temperature, optimizing the rolling process and reforming the dri...

Cause analysis and control of roller ring explosion in Yangchun New Iron and Steel high line

2023-11-03

Abstract:According to the phenomenon of tungsten carbide roll explosion in high line of Yangchun New Iron and Steel rolling mill, this paper analyzes the causes of tungsten carbide roll explosion in detail through site...

Analysis and control measures of buckle head in rolling process of wide and thick plate

2023-10-24

Abstract: This paper mainly analyzes the reasons why the head and tail of the rolled piece often buckle in the production process of the 4300 wide and thick plate production line of Laiwu Iron and Steel Co., LTD., and gives...

Analysis and improvement of seam adjustment and misalignment of flat/vertical conversion mill

2023-10-08

Abstract:Due to the particularity of the use of the flat/vertical converter, the design, manufacture and use of the rolling mill have higher requirements in the actual use of the site, if the design and manufacture are...

Analysis and treatment of pile steel problems in high line production

2023-09-06

Abstract: The paper analyzes the causes of some typical stacking accidents in the process of high speed wire rod production in the rough rolling area, pre-finishing area, finishing rolling area, pinch roll, spinning machine are...

Process improvement of pinch roll in high speed bar production line

2023-09-01

Abstract: High speed bar products are generally used in the cooling bed after the segment of the first pinch and then brake. The finished products will produce pinch marks on the surface after the pinch roll, which will affect ...

Practice of accelerated rolling in ultra-thin tropical production

2023-08-12

For ultra-thin specification products, the thinner the thickness, the greater the temperature drop during rolling. Increasing the speed of rolling is one of the effective methods to ensure reasonable final rolling temperature a...

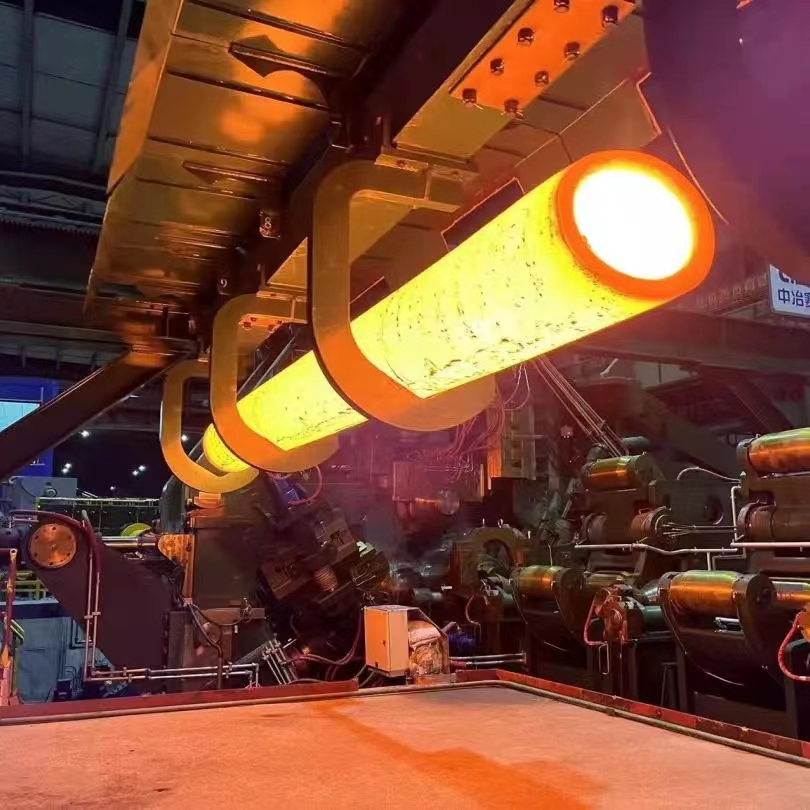

Improvement of cracking of hot rolled strip steel

2023-08-01

The production process of hot rolled strip steel: Liquid iron pretreatmentA top and bottom double-blown converter a deoxidation alloying a blown argon a slab continuous casta casting billet testa heating a roughing high-pre...

Fault analysis of automatic baler for high line

2023-07-24

Abstract This paper mainly introduces the structure, working process and the problems existing in the actual production process of the high line automatic baler and their solutions. keyword High line rolling mill, a...

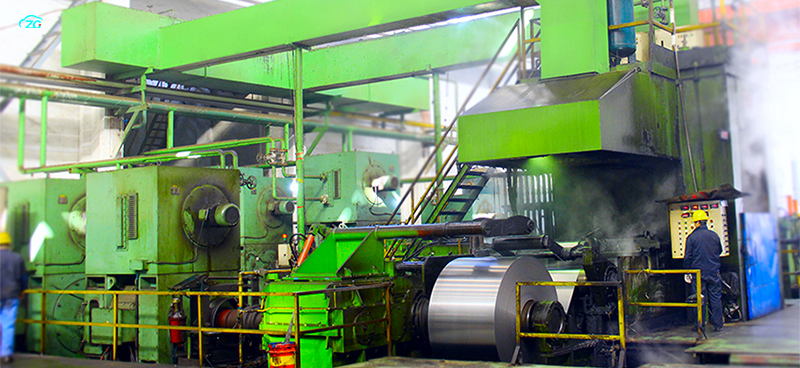

Main defects and analysis of strip steel rolling, hot rolling technology

2023-07-21

The main defects caused by rolling strip steel on a tropical mill are as follows: (1) Scar. The cracks and cracks were not completely removed when the slab was cleaned, resulting in scarring during rolling. Slabs...

Finishing area process technology operating rules, rod line technology

2023-07-05

1. Cold bed 1.1. effect After rolling, the double ruler is accelerated, braked, and sent to the cold bed for cooling and grouping to ensure that the double ruler on the cold bed is straight and one...